This stuff keeps getting better! In the above photo, you see all the tools necessary for the bulkhead installations. This is as simple as it gets. All the bulkheads, consoles, panels, and stringers are scribed into the flat stock that comes in Kit "B" (all vacuum bagged, of course!). All the builder has to do is cut to the outside of the line, sand to perfect fit and install into the fuselage. Most of the critical bulkhead placement points are scribed into the fuselage at the factory. So, line up the marks...and as we say - "pookie-it into place" with 2" wide BID glass tapes. Make no mistake, this is where Berkut has really left the other kits behind - there is very little parts preparation or jigging...THE PARTS FIT first time out of the box!

The main bulkheads are as follows: the front nose gear, F10 canard mount, instrument panel and consoles, front pilot seat and air-brake actuator, forward baggage door and rear pilot seat bulkhead. This stage of the building process is VERY rewarding. Unlike some other tedious areas of building, here a little fast work goes a long way toward a finished part.

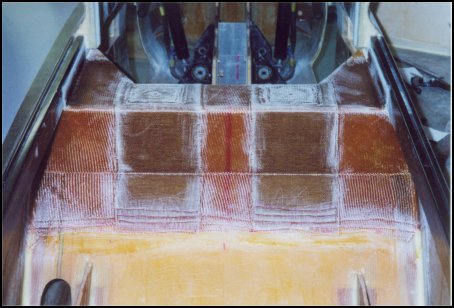

UPDATE: I guess this is as good a place as any for this section - it is part of Kit 'C' but it goes with the bulkhead installs. This structure holds phenolic hardpoints for the pilot's harness. Since the original prototype was produced, the rear facing triangles were added to increase the bonding area for the many plys of BID.

First, the bulkhead material is cut, shaped to fit and bonded in place. (you can see the phenolic squares installed in the bulkhead material) Then many plys of BID are layed up from side to side lapping onto the longeron. Long pads od UNI glass are added on top of the hardpoints that run down the aft face of the seat, and additional 4X4 inch BID pads are also placed on top. The end result is a rock solid support that really stiffens the fuselage too.

Back to the Proto-page

Back to the Proto-page